Moving Clothes Filter Press(Auto)

A Moving clothes type filter press is a breakthrough of general filter press. It is a highly efficient, compact, dewatering device for separating solids from liquid slurries in the form of compressed cake. Its major components are a structured framework, filter chambers (formed by recess portion of Recessed plate system, or frames in plate and frame system), and filter cloth.

Filter press technology although very basic in nature, but its application is as important to the various processes it serves, as is a simple wheel to the motive machines. Filter Press are separation devices used for solid or liquid separation that work on feed pressure or squeeze pressure to reduce liquid content in process or waste slurries or to reduce solid content in a product.

- Complete automatic operation

From the initiation, dewatering, and cleaning filter clothes to the release of sludge, all the above operate automatically. Batch operation and operating time can be set for everyday. The entire process is completely manpower-free. The dryer is suitable for 24-hour continuous operation, and can save the cost of investment. - Efficient dewatering to high dryness

By entry of mud at the top of the filter plates, a uniform distribution of entered sludge can be achieved. Each filter plate is equipped with a high-tension membrane. By applying uniform squeezing of the membrane, the sludge cake will reach high dryness at the shortest period of time. - Complete release of mud disks, no contaminations on filter clothes

Because of the filter-clothes moving design, even the sludge cake that are difficult to be released can be automatically removed with ease when the clothes are zigzagging. - Fast cleansing of filter clothes

Because of the moving filter-clothes design, the cleansing of filter clothes can be finished quickly within one minute. With such ease of operation, the filter clothes will be kept clean, and thus maintain a stable dewatering efficiency over the long term. - Extreme heavy duty cleaning for mud treatment

Since there is a drastic reduction of time needed for dewatering, sludge release and filter clothes cleansing, the capabilities of the dryer increase greatly. In other words, by utilizing a smaller size of dryer, a targeted amount can be promptly treated. Therefore, it will save the factory space and the area for facilities.

A Moving clothes type filter press is a breakthrough of general filter press. It is a highly efficient, compact, dewatering device for separating solids from liquid slurries in the form of compressed cake. Its major components are a structured framework, filter chambers (formed by recess portion of Recessed plate system, or frames in plate and frame system), and filter cloth.

Filter press technology although very basic in nature, but its application is as important to the various processes it serves, as is a simple wheel to the motive machines. Filter Press are separation devices used for solid or liquid separation that work on feed pressure or squeeze pressure to reduce liquid content in process or waste slurries or to reduce solid content in a product.

- Complete automatic operation

From the initiation, dewatering, and cleaning filter clothes to the release of sludge, all the above operate automatically. Batch operation and operating time can be set for everyday. The entire process is completely manpower-free. The dryer is suitable for 24-hour continuous operation, and can save the cost of investment. - Efficient dewatering to high dryness

By entry of mud at the top of the filter plates, a uniform distribution of entered sludge can be achieved. Each filter plate is equipped with a high-tension membrane. By applying uniform squeezing of the membrane, the sludge cake will reach high dryness at the shortest period of time. - Complete release of mud disks, no contaminations on filter clothes

Because of the filter-clothes moving design, even the sludge cake that are difficult to be released can be automatically removed with ease when the clothes are zigzagging. - Fast cleansing of filter clothes

Because of the moving filter-clothes design, the cleansing of filter clothes can be finished quickly within one minute. With such ease of operation, the filter clothes will be kept clean, and thus maintain a stable dewatering efficiency over the long term. - Extreme heavy duty cleaning for mud treatment

Since there is a drastic reduction of time needed for dewatering, sludge release and filter clothes cleansing, the capabilities of the dryer increase greatly. In other words, by utilizing a smaller size of dryer, a targeted amount can be promptly treated. Therefore, it will save the factory space and the area for facilities.

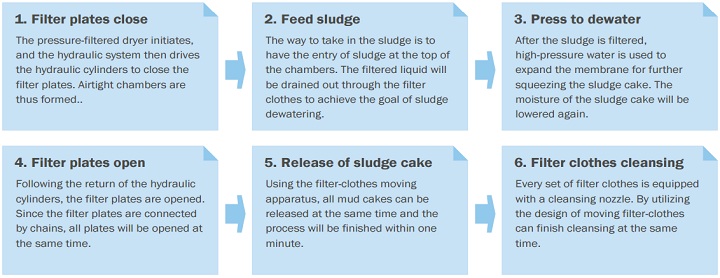

The principle of operation of the moving clothes type pressure-filtered dryer

The principle of operation of the moving clothes type pressure-filtered dryer

Applicable applications

Applicable applications

Food industry: Sugars, Beer, Flour, Soybean Sauce, Beverage, Grease, Saccharine, Artificial Flavor etc.

Chemical industry: Medicine, Fertilizer, Dye, Graphite.

Mining industry: Sand and stone pit, Marbles, Mount Morillonite, Bentonite, Calcium Carbonate, Amino Acid, White Smoke etc.

Others: Dyes, Resin, Metallurgic Industries, Non-iron Metallic Industries etc.

Polluted sludge in the sewer, industrial polluted sludge, and polluted sludge in the tap water etc.

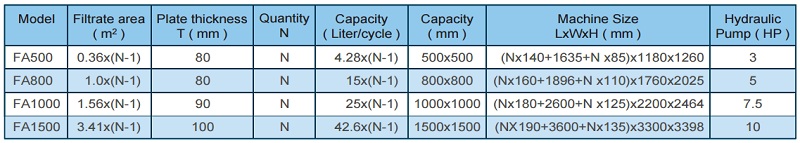

Moving Clothes Filter Press Specification table