BELT PRESS

Description:

Belt press type polluted sludge dryer is a kind of solid-liquid separating technology that integrates modern science. Due to the advantages of high efficiency in polluted sludge treatment, low maintenance fee, safe and reliable automatic operation brought by the belt filter type sludge dryer, it has drawn a lot of attention from worldwide technicians and engineers to complete its research and development.

Belt Filter Press treatment process

Description:

Belt press type polluted sludge dryer is a kind of solid-liquid separating technology that integrates modern science. Due to the advantages of high efficiency in polluted sludge treatment, low maintenance fee, safe and reliable automatic operation brought by the belt filter type sludge dryer, it has drawn a lot of attention from worldwide technicians and engineers to complete its research and development.

Belt Filter Press treatment process

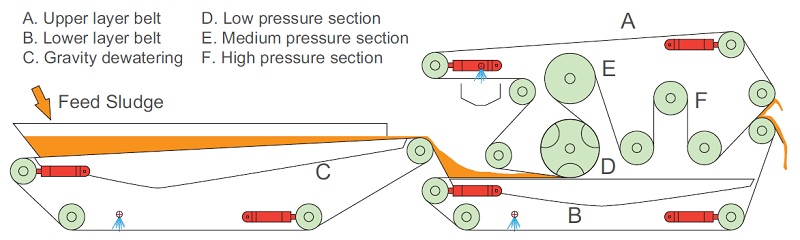

Operating procedures

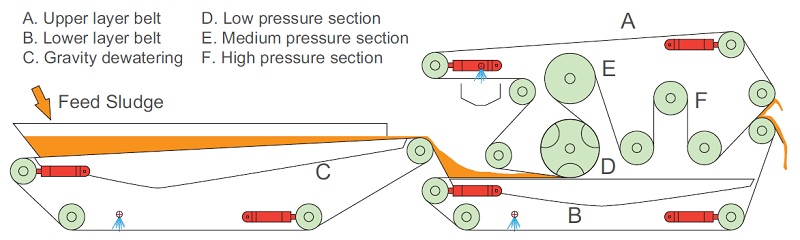

the process of dewatering includes mixing of the entering sludge, gravitational dewatering,wedge preloading, low-pressure roller, medium-pressure roller, and high-pressure roller for squeezing out of water.

- Mixing of the entering sludge: a unique design of tank mixing the polluted sludge and chemical agents at a constant speed for sufficient conglomerating reactions.

- Gravitational dewatering: a particular design of guiding plates and separators with appropriate mesh can remove a major portion of the water at the surface without destroy the conglomerate structure of the sludge.

- Wedge preloading: a method which applies the simple harmonic preload to incrementally increasing the pressure for stabilizing the entry of sludge and avoiding the lateral leakage of sludge.

- Low-pressure roller: uniform distribution of the holes on the surface is helpful for draining of a large amount of free water. By the effects of the relative velocity and the shear stress between filter clothes and roller, the slight rubbing will recombine the sludge.

- Medium-pressure roller: the key point is how to decrease the shearing surface on the small roller to increase the pressure gradually, so as to remove the capillary coupled water among sludge particles.

High-pressure roller: increases the filter clothes pressure and shearing force to the maximum to completely destroy the structure of the sludge and the membrane of the water molecules, and also press them up to the surface of the filter clothes to remove the colloidal water. The sludge is peeled off by a squeegee under shearing condition as well.

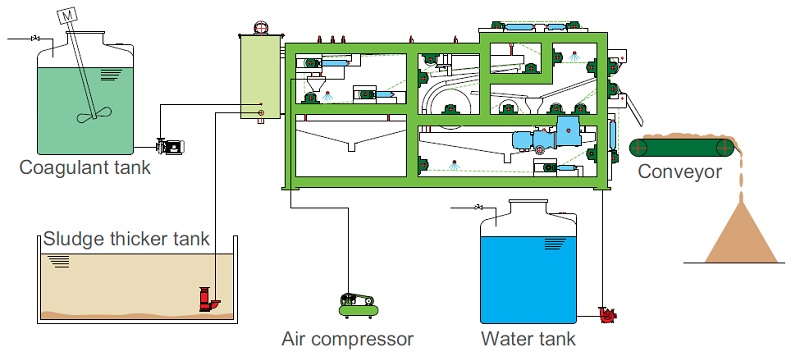

Belt Filter Press Flow Chart

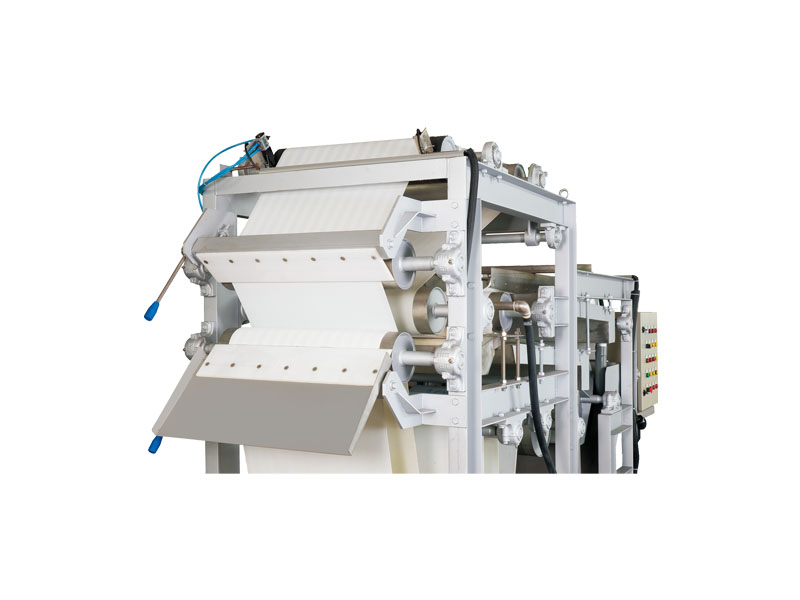

Product Characteristics

Product Characteristics

- Great capacity: continuous operation of high floe rate.

- Simple operation: automatic produced sludge.

- Tension controller for filter clothes: cranks are used to provide equal tension at both ends of the filter clothes, and also maintain a certain amount of pressure for filter clothes.

- Sludge equalizer: control the thickness and uniformity of the polluted mud entering the low-pressure roller.

- Adaptable cleaning: adjust the amount of cleaning water depending on the sludge condition. Save 50% or aboveof cleaning water.

- Pneumatic adjustment: pneumatic cylinders at two lateral sides accurately compensate the deviating movement of the filter clothes to avoid zigzagging and keep it flat and folded.

Wide application: any kind of sludge water can be treated by adding coagulants.

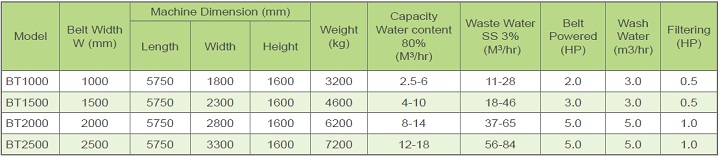

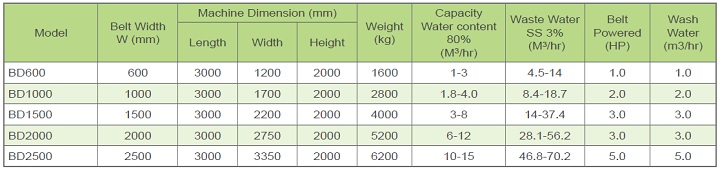

Double Belt Press Size

Three Belt Press Size

Three Belt Press Size